Build Your Own CNC Router Free Plan Download

This instruction will show how to built CNC router. Hope this build can draw some inspiration and this instruction will be helpful for your future projects. I went through in designing and building this CNC router.

Before starting, we need a design. this machine a more precise three dimensional drawing was required CAD. I design by using FreeCAD. FreeCAD is a freeware CAD program, which you can download from the web.

These are the basic dimensions and parts used for the machine:

Overall dimensions Travel

X: 1050 mm X: 1200 mm

Y: 840 mm Y: 800 mm

Z: 400 mm Z: 150 mm

|

| ISO Metric View |

|

| Front View |

|

| Side View |

Mechanical Part List

- Linear rails: X - SBR 20 | Y/Z - SBR 16

- Ballscrews: X/Y - 16mm pitch 5mm

- Motor: NEMA23

Buying a kit that includes linear rails and ball screws can save a lot of money.

The machine is almost entirely built from 10 mm thick aluminum plate and 40x40mm aluminum extrusions.

Before build a CNC answer these questions to determinate material for build CNC.

|

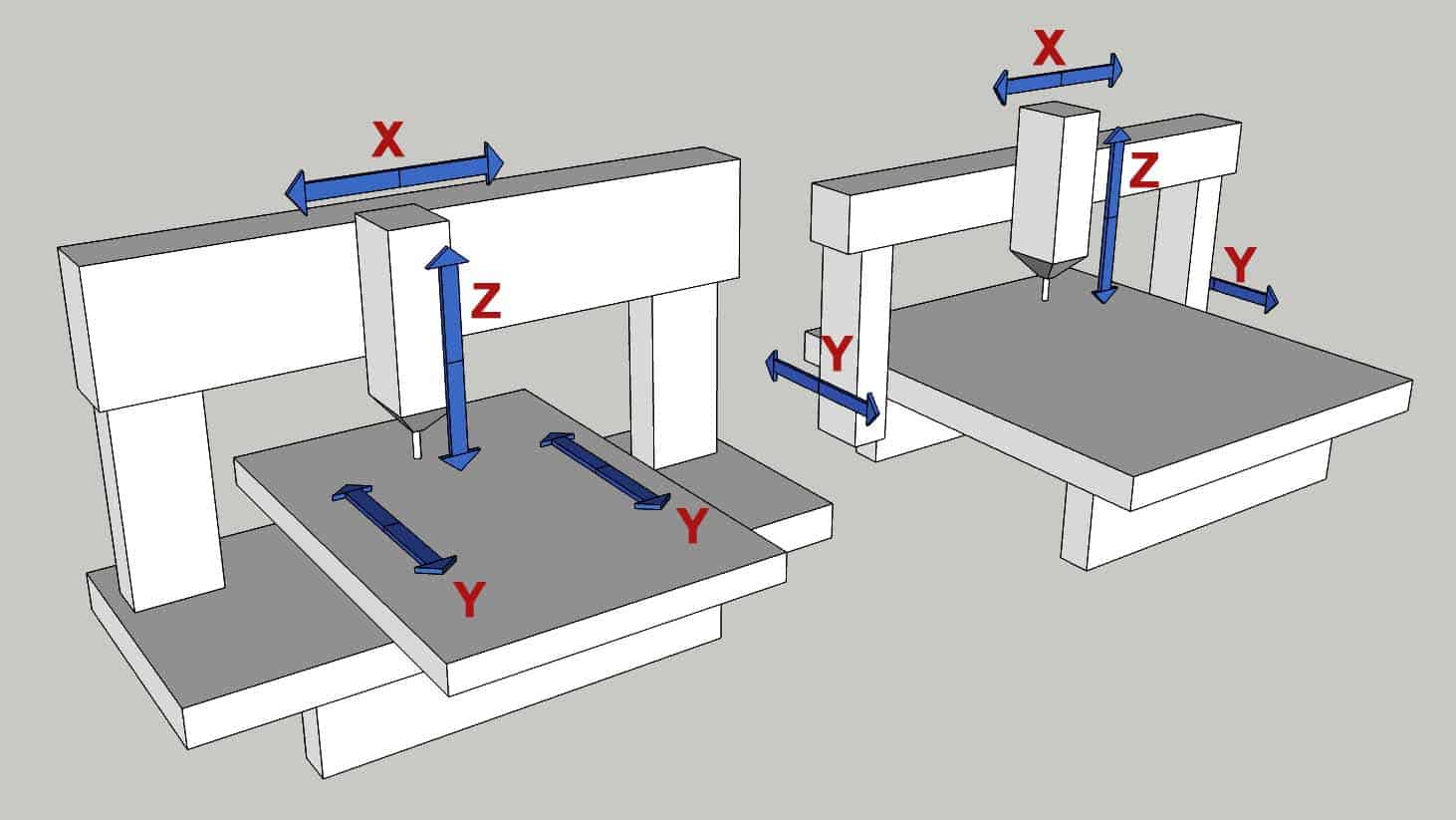

| Fixed Gantry and Moving Gantry Credit: CNC Chronicle |

Type of CNC that want to build

There basically are two types of CNC routers: the moving table design and the moving gantry design.

- Moving table style designs are often used for smaller size CNC routers. Easier to construct and can be built more rigid than a moving gantry style machine.

- The downside of letting the table move instead of the gantry, is that the overall footprint of the machine in retrospect to it’s cutting envelope, is about twice as large as with a moving gantry design. Therefore it probably is better to make a moving gantry style machine.

Material use to cut

This determines pretty much every answer to the topic below. I wanted to use the machine for plywood, hardwoods and plastics mainly, but also for aluminum. If you want to cut materials harder than aluminum, I recommend building a CNC mill, instead of a router.

Material use to construct the machine

This is determined by the topic above. A good guideline is that the material use to construct the machine is stronger or as strong as the material that want to cut. So if want to cut aluminum, you should use aluminum or even steel to build the machine. There're some wooden CNC routers that can cut aluminum (you will find some on YouTube), but this went very slow and the machines have to be very well constructed. Because I wanted to cut some aluminum with this CNC, I built it out of aluminum profile. We could have used steel, but this is more difficult to machine and I didn’t have the proper tools for that.

Length of travel for each axis

To build a CNC router that could handle standard size sheet goods, like plywood and MDF Board.

- So the X - axis has 1200 mm of travel. and Y - axis, a travel distance at least 800 mm. due for various material sheet and size

- For the Z - axis 150mm that would be enough to possibly use a fourth axis in the future.

Linear motion for the machine

There are many options to choose from for linear motion that fully supported linear rails would be the best option, that still could afford. If you search on ebay or AliExpress for SBR12, SBR16 or SBR20 you will find a number of different sellers and sets to choose from. If you are building a 3 axis CNC, you should buy a kit consisting of three sets of linear rails and two linear bearings per rail.

Linear drive system use for each axis

The basic options to drive each axis are drive screws are most commonly used. Screw drive systems work by placing the stationary nut on the moving part of the machine and holding the screw in place on both ends. The screw gets attached to the motor. If the motors starts to turn, the nut with the moving part of the machine attached to it, will move along the screw and set the machine in motion.

For the X and Y axis, I used ball screws. Ball screws provide very smooth motion, with virtually no backlash. Backlash is the amount of play between the drive screw and the nut that is something you don’t want in a CNC. If you want to read more about backlash here.

For the Z-axis I used high quality stainless steel M10 threaded rod, with a homemade Delrin Anti-backlash nut.

If you have problem with design CNC you can comment below to ask question

ความคิดเห็น

แสดงความคิดเห็น